INNOTECH|Fertigungstechnik

Top-level production made in Austria.

In addition to the production of fall protection protection articles for INNOTECH Arbeitsschutz GmbH, the company also produces components for other well known companies, such as Fronius, MELTEC, Reform-Werke Bauer and many more.

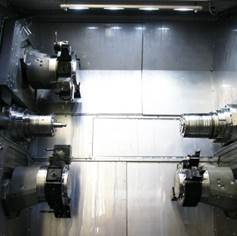

In the areas of turning, milling, edging, welding, sawing, abrading, installation, laser engraving and digital printing, the company provides production to the highest standards.

Customer requirements are implemented flexibly, quickly and to the highest quality. If desired, the products are packed, assembled and of course delivered on time - either directly to the purchaser's warehouse or to their customers.

In order to completely fulfil our own extreme demands for quality, safety, and cleanliness, we pursue a zero-error strategy which is reflected in all our processes.

DIGITAL PRINTING.

We provide the maximum variety for your publicity material. Our very modern digital printing machines can print and cut in just one single step - for individual small runs as well as large orders.

Our production portfolio includes stickers, banners, labels, posters, photos, advertising signs, and even car graphics, textile printing, etc.